Cnc Beam Drill Line Review

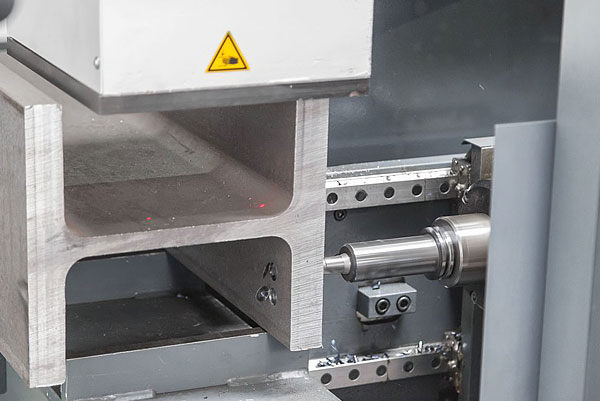

The Franklin HD145 (3) CNC spindle drill has a 44-inch width. The HD-145 can handle beams up to 775 lbs per foot. High-performance spindles are capable of drilling at speeds up to 2,000 RPM. This rigid design allows for extremely fast feed rates of up to 300 feet per minute. You can order the Franklin HD145 with a variety of material handling packages, ranging from 300 lbs per feet to 750 lbs each foot.

Material handling allows multiple CNC machines to be connected and maintains material flow through a shop. This allows fabricators the opportunity to continue growing as their business grows. Only the Advantage-2 high-speed drilling line can produce 150 tons of metal per 40-hour working week. This is the perfect drill line for small and large fabricators worldwide. Complete stop. Voortman puts the success and well-being of the steel sector as his top priority. This is why we offer unsurpassed support and service. For more information about the most difficult steel fabrication machinery worldwide, contact us to request a demo. Voortman, we are stronger than any steel.